ADVANCED MANUFACTURING & ENGINEERING CAPABILITIES

GEM Manufacturing, a PrecisionX Group company, specializes in Deep Drawn Metal Stamping, CNC Milling, CNC Turning, and Wire EDM to produce high-precision, critical metal components.

Core Capabilities

Deep Drawing

Our deep draw expertise allows us to create complex, high-tolerance metal components from durable materials, ideal for industries requiring precision and strength, such as aerospace, medical, and defense.

Progressive Stamping

We deliver high-volume, precision metal parts through progressive stamping, ensuring consistent quality for industries like aerospace, automotive, and medical, where efficiency and accuracy are critical.

PrecisionX Full Capabilities

The PrecisionX Group offers a robust portfolio, including deep drawing, progressive stamping, CNC machining, Swiss machining, laser marking, laser welding, and more. With expansive facilities and expertise across multiple industries, we provide solutions for your complex manufacturing needs. Brands include: GEM, Coining, National Manufacturing, Ditron, MSK Precision Productts.

Industries & Applications Served

Aerospace & Defense

In aerospace and defense, materials that perform reliably in harsh environments are essential. We specialize in high-performance metals like Inconel, Titanium, and Hastelloy, engineered to withstand extreme conditions. Our expertise ensures your parts meet strict industry standards for mission-critical success in even the toughest environments.

Medical Device

Precision is the foundation of success in the medical device industry. We manufacture your high-reliability components to meet stringent regulatory standards, ensuring accuracy, durability, and performance in life-saving devices. Our expertise in deep draw technologies and tight tolerances enables us to support the development of innovative medical solutions.

Satellite & Space

We bring unmatched precision and innovation to the satellite and space industry, producing critical components that must perform in the most extreme environments. Our advanced progressive stamping and deep drawing capabilities allow us to craft complex, high-strength metal parts with the tight tolerances required for space applications.

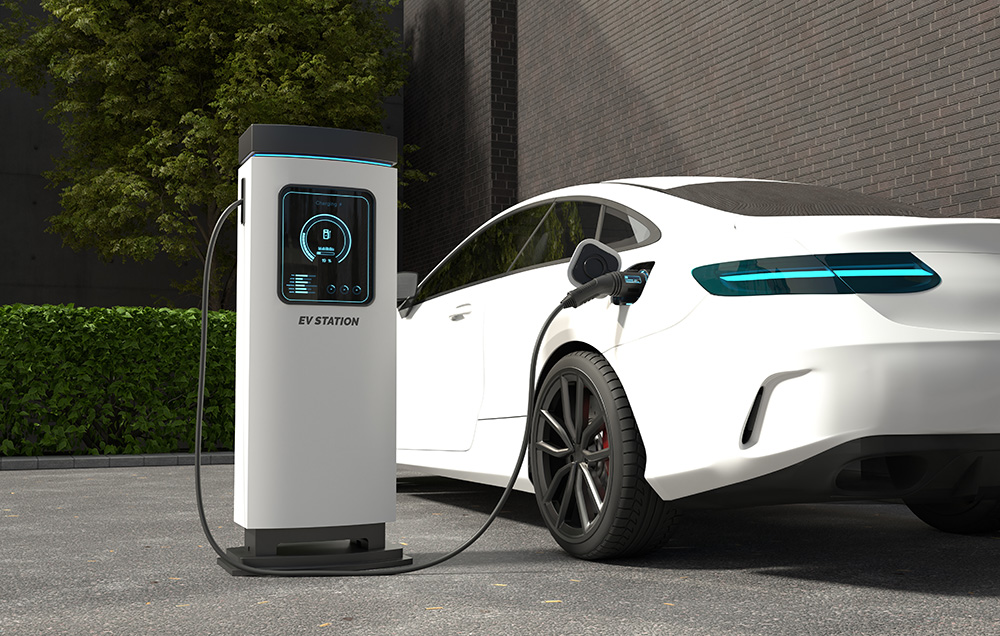

Electric Vehicle

As the need for innovation accelerates, we partner with our customers’ engineering teams to manufacture the critical components that power the next generation of EVs. From precision metal parts to advanced manufacturing solutions, we deliver excellence.

Mining

In the mining industry, precision and reliability are essential. Blasting caps and other critical components are crafted to perform in the harshest environments. By partnering with your engineers, we deliver durable, high-quality solutions that ensure efficiency.

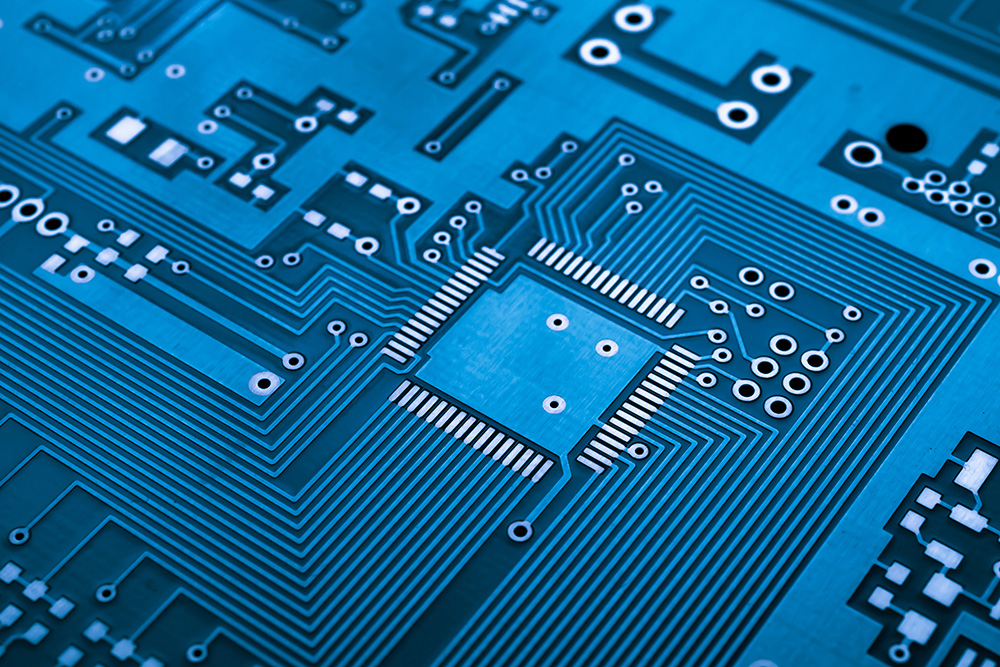

SemiConductor

Our advanced capabilities in metal forming, stamping, and machining ensure the highest quality parts for critical PCB applications. Whether it’s connectors, shields, or custom components, we manufacture to exacting specifications, providing reliable and durable solutions that enhance PCB performance.

Fire Suppression / Sprinkler

We provide high-precision metal components specifically designed for fire suppression and sprinkler systems. Our expertise in metal forming ensures the production of reliable parts like copper buttons and brass inserts, which are crucial for the functionality and safety of these systems. With exact press-fit assemblies and durable materials, our components are engineered to withstand extreme conditions and perform flawlessly when needed most.

Capacitor

We specialize in manufacturing precision-engineered parts designed to meet the high-performance demands of capacitors used across various applications, from electronics to power systems. With expertise in working with advanced metals and alloys, we ensure that every component is manufactured to exact specifications, providing reliability and durability. Whether for high-volume production or custom designs, PrecisionX delivers the quality and precision required for capacitor manufacturing.

Eyelets / Ferules

We manufacture eyelets and ferrules for a wide range of applications. Our advanced metal forming capabilities allow us to produce high-quality, durable components that meet exacting specifications. Whether used in electrical connections, medical devices, or industrial applications, our eyelets and ferrules are engineered for strength, reliability, and seamless integration. With our expertise in working with various metals, including stainless steel, copper, and brass, we ensure consistent quality and performance in every part we manufacture.

About Us

GEM is a PrecisionX Group company. Headquartered in Waterbury, Connecticut, PrecisionX Group is a leading provider of precision metal components for critical-use applications in key growth markets, including aerospace & defense, medical device, satellite and space, electric vehicles, mining, semiconductors, and other industrial sectors.

Utilizing advanced technologies such as deep draw and progressive stamping, Swiss screw machining, CNC, and wire EDM, PrecisionX handles projects from development to high-volume production.

With a global footprint exceeding 250,000 square feet, the PrecisionX portfolio includes MSK Precision Products, Ditron, Inc., National Manufacturing, GEM Manufacturing, and Coining MFG. Certifications include, ISO 9001:2015, ISO 13485:2016, AS9100, and ITAR Registered.

As a customer of PrecisionX, you are partnering with a team driven to:

- Uphold an uncompromising commitment to Quality

- Create the best possible Customer Experience

- Maintain Technical Leadership across highly complex parts

- Accelerate Speed to Market from quote to delivery